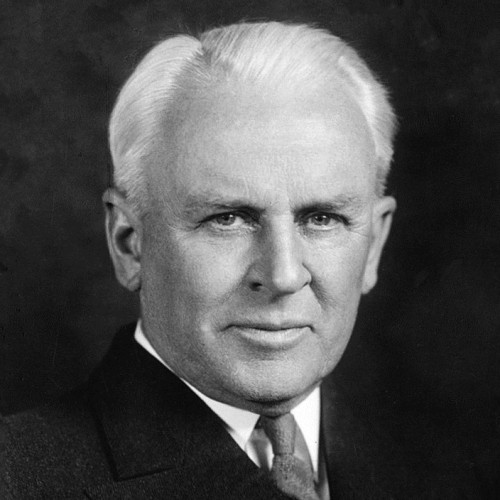

Robert Andrews Millikan

Science walks forward on two feet, namely theory and experiment.

Cavitation occurs when the static pressure drops rapidly below a certain critical pressure. This leads to the formation of vapor-filled cavities (gas bubbles) in a liquid’s flow. The bubbles collapse again shortly after their formation, which leads to high pressure surges, material damage, sound emission and changes in the operating behaviour within the affected system. Cavitation is a research topic not only because of its negative effects in maritime applications and hydraulic machinery. It is also profitabely used for surface cleaning of solid surfaces by means of ultrasound. This effect is applied in the semiconductor industry and is based on the generation of cavitation by sound waves (acoustic cavitation). Furthermore, the cavitation’s destructive influence on bacteria and particles allows cavitation to be used for wastewater treatment. Considering lithotripsy (physical destruction of kidney stones), the effects of cavitation are also used in the medical field. We experimentally explore the nucleation process of cavitation, i.e. the formation of bubbles and nuclei, cavitation erosion and the dynamics of large cavitation structures (sheets, clouds). We also develop analytical models to describe these processes and validate them using the obtained experimental data.

Turbomachinery is an important element of our modern civilization. They consume about 30% of the electricity consumed in industry, but also generate, for example, over 50% of the UK's energy needs. For economic reasons, turbomachinery often does not operate at the design point where efficiency is best. In this part load operation regime, various secondary flow phenomena occur, such as cavitation, rotating stall, and part load recirculation that reduce both efficiency and operational reliability. Considering the significance of turbomachinery, we are dedicated to study these phenomena. Partial load recirculation occurs when the flow rate falls below a critical value, followed by separation and recirculation of the flow. Separation and recirculation lead to an undesired change of the velocity profile, shear stress, dissipation and turbulence of the boundary layer.